Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: WF-125-W

Brand: SKYIMG

Material: Pet

Types Of: Twist Film

Use: Food&Amp;medicine Film

Special Performance: Moisture Proof

Hardness: Soft

Transparency: Translucent

Place Of Origin: China

Usage: Food&Amp;Medical Film

Types Of: Twist Visible Film

Hardness: Soft

Color Temperature: Daylight Type

Sensitivity: Medium-sensitivity Film

Base Material: Polyester(PET)

Packaging: 100 sheets together in the plastic bag,then together in the yellow corrugated carton,yellow corrugated carton together in the non fumigation pallet

Productivity: 100000Square Meter/Square Mete

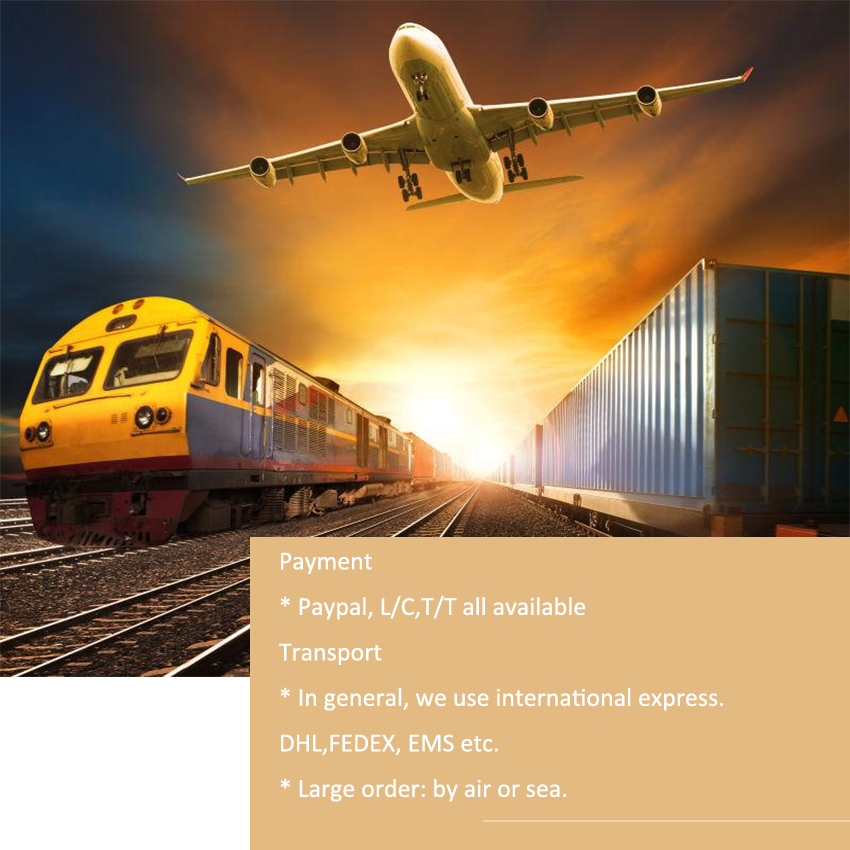

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 100000000 Square Meter/Square Meters per Month

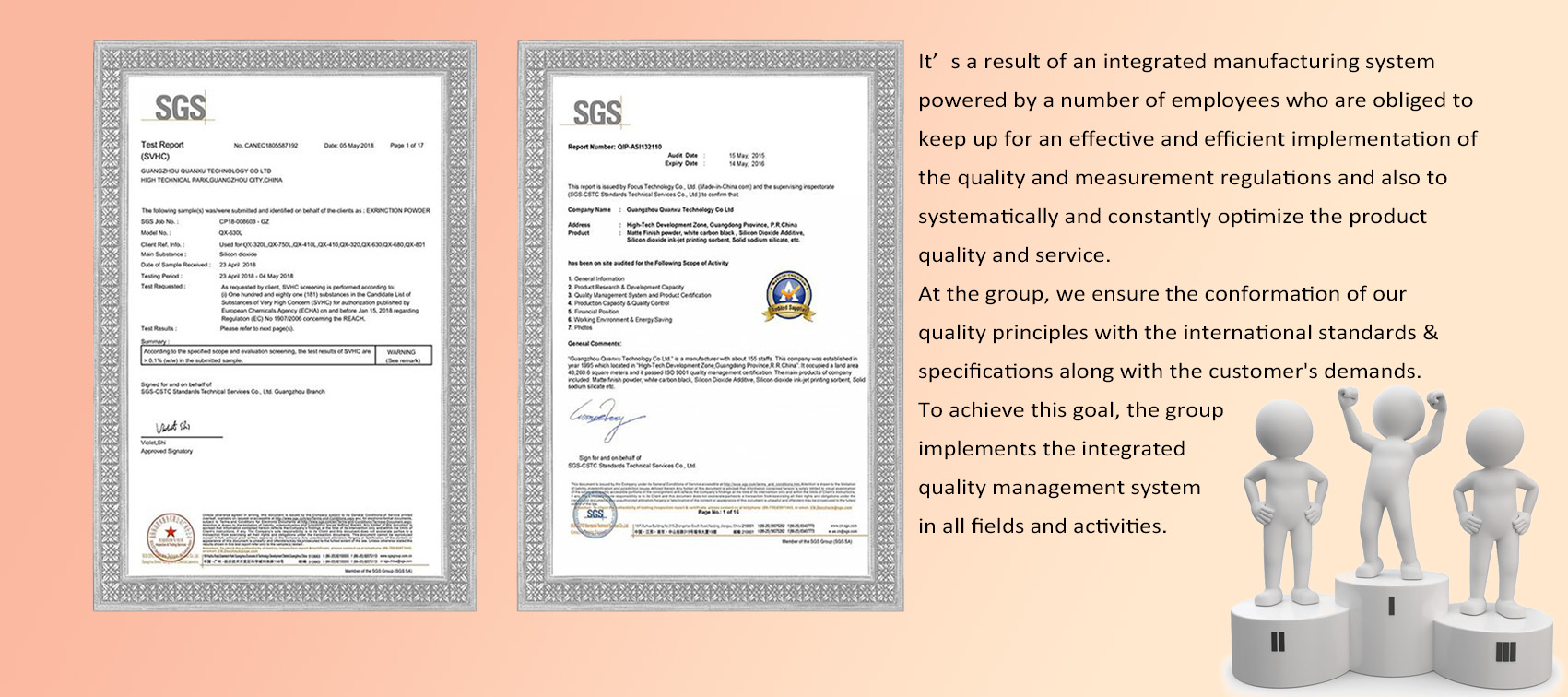

Certificate: SGS

HS Code: 3920690000

Port: Guangzhou,Shenzhen,Shanghai

Payment Type: L/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,CIF,EXW

The application of silicon dioxide in medical coating protective films is mainly reflected in its unique physical and chemical

properties. Silicon dioxide, also known as silicon dioxide, is an inorganic non-metallic material with good corrosion resistance,

wear resistance, high temperature resistance, and good light transmittance. In medical coating protective films, silicon dioxide

can provide the following functions:

1. Wear resistance: The surface of medical equipment often needs to contact various liquids or equipment friction. Silicon dioxide

can increase the hardness and wear resistance of the coating and protect the surface of the equipment from damage.

2. Corrosion resistance: Many medical environments contain acidic and alkaline substances. Silicon dioxide can form a protective

layer to prevent these substances from corroding the surface of the equipment.

3. Heat insulation and insulation: In some occasions where heat insulation or electrical insulation is required, silicon dioxide can

provide excellent performance.

4. Light transmittance: For medical equipment that requires transparency, such as dialyzers, contact lenses, etc., silicon dioxide

can be made into a transparent protective film without affecting the normal use of the equipment.

5. Beauty and cleanliness: The surface of the silicon dioxide coating is smooth and easy to clean, which helps to keep the medical

equipment hygienic.

In general, the application of silica in medical coating protective films is an important part of improving the service life and user

experience of medical equipment.

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent, PET

Product Categories : Matting Agent For PET Film > Medical Film

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.