Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: WF-125-WD

Brand: SKYIMG

Material: Pet, Polyester

Types Of: Twist Film

Use: Food&Amp;medicine Film

Special Performance: Moisture Proof

Hardness: Soft

Transparency: Translucent

Place Of Origin: China

Usage: Visible Film

Sensitivity: Medium-sensitivity Film

Color Temperature: Daylight Type

Base Material: Polyester(PET): Base Thickness: 125 Microns

Color: Blue: Surface: Glossy

Printable Side: Double Sides: Compatible Printer: Inkjet Printer

Package: Neutral Export Package

Packaging: 100 sheets together in the plastic bag,then together in the yellow corrugated carton,yellow corrugated carton together in the non fumigation pallet

Productivity: 100000Square Meter/Square Mete

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 100000000 Square Meter/Square Meters per Month

Certificate: SGS

HS Code: 3920690000

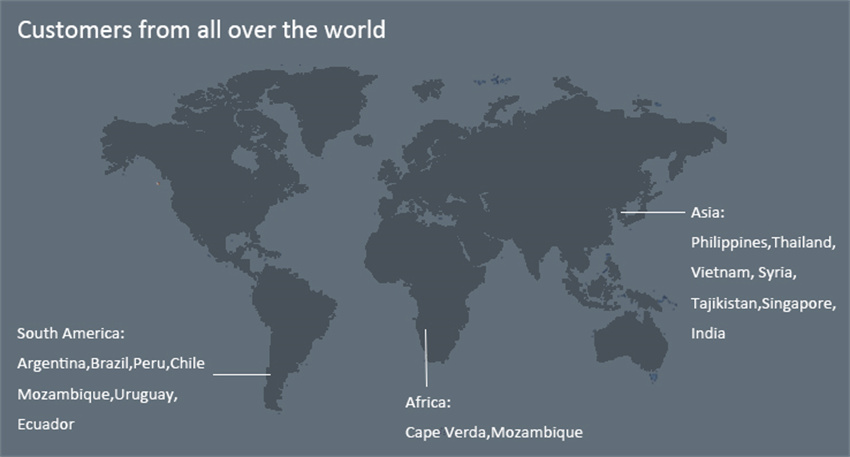

Port: Guangzhou,Shenzhen,Shanghai

Payment Type: L/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,CIF,EXW

How to choosing silica Matting Agent in medical film coating?

* Ideal matting effect

(1) Choosing large particle size. The even particle size of silica matting agent is larger, the matting effect is more effective.

But if the particle sizes is too large will make the coating's surface rougher to affect the feel and appearance.

* Ideal transparency

(1) When the amount added in the formula is the same, the smaller the average particle size of the matting agent, the better

the transparency of the paint film, but the corresponding matting efficiency will also decrease. It should be pointed out that too

high a fine powder content will have a negative impact on transparency.

(2) Surface treatment. Due to the different types of surface treatment of the matting agent, it will affect its wetting and

dispersibility with the base material, thereby affecting the transparency of the paint film. Therefore, it is necessary to adjust the

matching between the matting agent and the base material, and if necessary, it can be improved by adding a wetting and

dispersing additive. At the same time, it is also necessary to pay attention to whether there are other factors that cause the

transparency of the paint film to deteriorate, such as additives with poor compatibility or poor pigments.

* Ideal suspension performance

(1) Generally speaking, matting agents will delaminate and precipitate to a certain extent as the storage time of the coating

increases. Products with organic surface treatment will have better anti-settling properties. Therefore, when designing the formula,

we should consider how to avoid the precipitation of matting agents and add appropriate anti-settling additives.

* Ideal scratches resistance

The surface of the matting agent has been organically treated, which will improve the scratch resistance and wear resistance of

the paint film to a certain extent.

Performances of medical film coating with silica matting agent

1. Adopted on excellent polyester(PET) material,produced by special coating technology.

2. Anti-static treatment,100% waterproof.

3. The white glossy surface,anti-skidding,anti-adhesion,suitable for long-term preservation.

4. High ink coverage and resolution,accurate and true image,outstanding color gamut wide.

5. Widely used for inkjet printing,the output of medical image such as X-ray, CT, NMR and PET - CT ,thephotograph,digital

printing etc.

6. Environmental non-toxic,without any peculiar smell and harmful gas.

7.Compatible with most kinds of inkjet printers and all desktop printer,such as Epson,Canon,Fuji Xerox,HP, OKI etc.

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent,PET

Product Categories : Matting Agent For PET Film > Medical Film

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.