Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: WF-125/150-W

Brand: SKYIMG

Material: Pet, Polyester

Types Of: Twist Film

Use: Food&Amp;medicine Film

Special Performance: Moisture Proof

Hardness: Soft

Transparency: Translucent

Place Of Origin: China

Usage: Visible Film

Sensitivity: Medium-sensitivity Film

Color Temperature: Daylight Type

Base Material: Polyester(PET): Base Thickness: 125 Microns

Color: White: Surface: Glossy

Printable Side: Single Side: Compatible Printer: Inkjet Printer

Package: Neutral Export Package: Suitable Ink: Water Based Dye And Pigment Inks

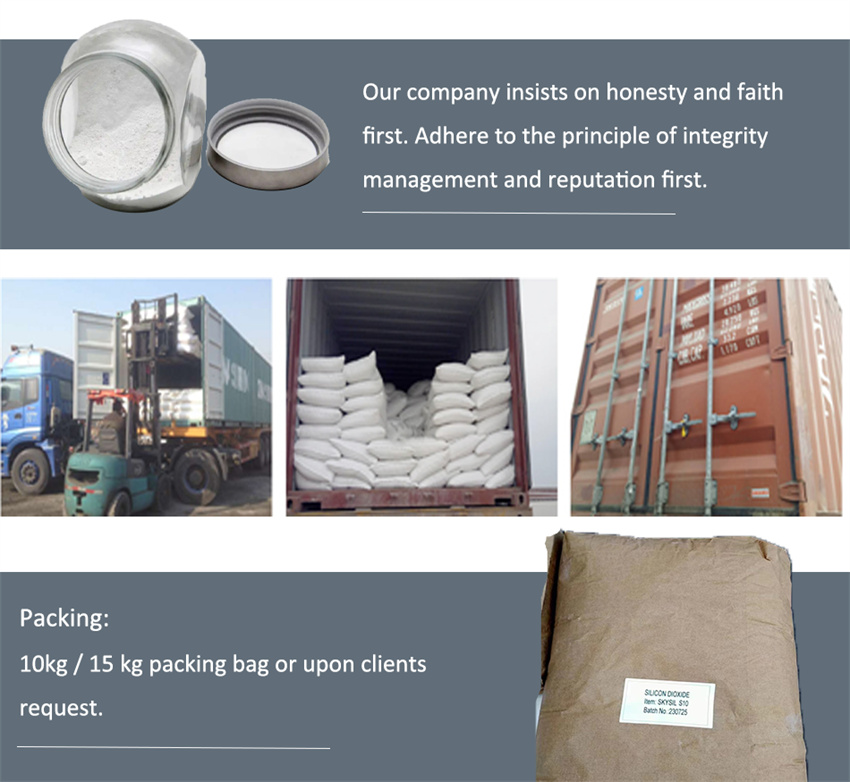

Packaging: 100 sheets together in the plastic bag,then together in the yellow corrugated carton,yellow corrugated carton together in the non fumigation pallet

Productivity: 100000Square Meter/Square Mete

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 100000000 Square Meter/Square Meters per Month

Certificate: SGS

HS Code: 3920690000

Port: Guangzhou,Shenzhen,Shanghai

Payment Type: L/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,CIF,EXW

How can silica Matting Agent works in medical film?

Precipitated silica, also known as silicate or silica gel, is a common inorganic non-metallic material that is widely used in

the medical field, especially in medical film coatings. Its main advantages include:

1. Chemical resistance: Precipitated silica has good acid and alkali resistance and corrosion resistance, and can resist

various chemicals in the medical environment.

2. Biocompatibility: Properly treated precipitated silica has good compatibility with biological tissues and does not cause

obvious immune reactions.

3. Highly customizable: By changing its particle size, shape and surface properties, its performance in the film, such as

adsorption capacity, optical properties, etc., can be adjusted.

4. Thermal stability: In the high temperature environment of medical equipment, the performance of precipitated silica is

stable and not easy to decompose.

In medical film coatings, precipitated silica can be used as a carrier for drug loading and release, or as a functional layer to

provide specific physical or chemical properties. For example, it can be used to make films that are antibacterial, anti-adhesive,

oxygen-permeable, or block specific substances. However, the specific application will be adjusted according to the specific use

and design of the film.

What can we use medical film for ?

1) The surface of the film presents a white luster, which is non-slip and non-bonding, suitable for long-term preservation.

2) High-quality polyester (PET) materials are selected and produced by special coating technology.

3) It can be 100% waterproof and have the ability of anti-static treatment.

4) The surface of the film is white and shiny. It is non-slip and non-adhesive, suitable for long-term preservation.

5) High ink coverage and resolution, accurate and real image, wide color gamut.

6) It is widely used for ink-jet printing and medical image output, such as X-ray, CT, NMR, pet-ct, photo, digital printing, etc.

7) Environmental friendly and non-toxic, without any peculiar smell or harmful gas.

8) Compatible with epson, Canon, Fuji xerox, HP, OKI and most types of inkjet printers and all desktop printers.

Furthermore, the high purity of silica dioxide sand minimizes the risk of contamination in the medical film production process.

Contaminants can negatively impact the quality of the film and compromise patient safety. Therefore, using top grade silica

dioxide sand helps to maintain the integrity of the films and ensures accurate and reliable medical imaging.

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent, PET

Product Categories : Matting Agent For PET Film > Medical Film

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.