Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: SL-801

Brand: SKYSIL

Place Of Origin: China

Main Ingredient: Acrylic, Epoxy, Nitrocellulose, Polyurethane

Application Field: Appliance Paint, Plastic Coating, Building Coating, Furniture Paint, Paper Coating, Car Paint

Instructions: Brush

Status: Powder Coating

Productivity: 100000 Ton/Year

Certificate: SGS/ISO9001

Brand Name: SKYSIL

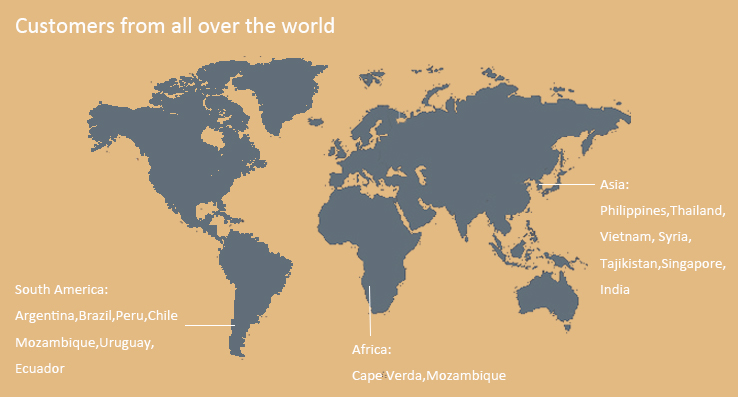

Transportation: Ocean,Air,Express,Land

Packaging: 10 kgs/bag, 360 kgs/Pallet, 20 fcl 3.6 Ton With Palletized, 4.5 Ton Without Pallet.

Productivity: 100000 Ton/Year

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 100000 Ton/Year

Certificate: ROHS

Port: Nansha,Hongkong

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW

Feature

When selecting a silica agent for UV-cured coatings, you'll want to consider several factors to ensure it meets the specific

requirements of UV curing while providing desired properties in the final coating. Here are key considerations for choosing

a good-quality silica agent:

UV Transparency: The silica agent should be transparent to UV light to allow effective curing of the coating. Transparent

silica particles ensure that UV radiation penetrates through the coating layer to initiate the curing process.

Particle Size: Fine particle size is essential for achieving uniform dispersion in the coating formulation and maintaining clarity

in the cured coating. Smaller silica particles contribute to smoother coatings and minimize the risk of visible particles or

texture.

Surface Modification: Surface-treated silica particles can improve compatibility with the coating resin and enhance dispersibility, adhesion, and durability of the cured coating. Surface modification may also influence properties such as scratch resistance and

surface smoothness.

UV Stability: The silica agent itself should be UV stable to prevent degradation or discoloration of the cured coating over time

when exposed to UV radiation. UV-stabilized silica particles help maintain the performance and appearance of the coating.

Chemical Resistance: Ensure that the silica agent provides chemical resistance to the cured coating, protecting against solvents,

oils, and other environmental factors. Chemical resistance enhances the durability and longevity of the coating in various applications.

Dispersion Stability: The silica agent should disperse easily and uniformly in the coating formulation to achieve consistent curing

and overall coating performance. Good dispersion stability prevents issues like settling, agglomeration, or uneven distribution of silica particles in the coating.

Matting Effect: If a matte finish is desired in the cured coating, consider a silica agent that provides effective matting while

maintaining UV transparency. Silica matting agents can reduce glossiness and create a matte appearance in the cured coating.

Regulatory Compliance: Verify that the silica agent meets relevant regulatory standards and safety requirements for use in

UV-cured coatings, particularly concerning chemical composition, toxicity, and environmental impact.

Tips:

* Before you use it, please test and make sure the dosage before using according different formulations and conditions.

* Recommended dosage is 3% -5%.

| Item | SL-801 | Brand | SKYSIL |

| Content of SiO2,(dry basis) %≥ | 99 | Porosity,ml/g | 1.8-2.0 |

| DOA absorption ml / 100g | 230-270 | Particle Size(Malvent),um | 4.0-5.0 |

| Loss on drying (105℃,2Hrs),% | ≤5.0 | PH | 6.0-7.0 |

| Ignition Loss(1000℃,2Hrs),% | ≤13.0 | Whiteness≥ | 90 |

| Item | SL-802 | Brand | SKYSIL |

| Content of SiO2,(dry basis) %≥ | 99 | Porosity,ml/g | 1.8-2.0 |

| DOA absorption ml / 100g | 230-270 | Particle Size(Malvent),um | 6.0-7.0 |

| Loss on drying (105℃,2Hrs),% | ≤5.0 | PH | 6.0-7.0 |

| Ignition Loss(1000℃,2Hrs),% | ≤13.0 | Whiteness≥ | 90 |

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Product Categories : Matting Agent > Matting Agent For UV Coatings

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.