Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: SS-U70

Brand: SKYSIL

Place Of Origin: China

Application Field: Cosmetic Raw Materials, Detergent Raw Materials, Hair Care Chemicals, Oral Care Chemicals

Packaging: 10kgs/bag,360kgs/Pallet,20fcl 3.6Ton With Pallet 4.5tTon Without Pallet

Productivity: 10000Ton/Year

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 800Ton/Month

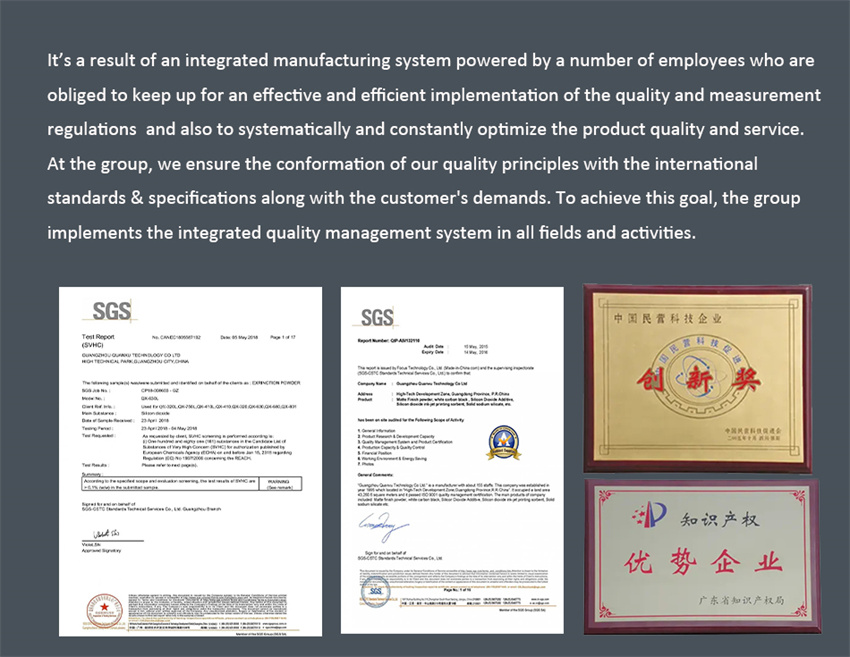

Certificate: ISO/SGS/ASTM / ROHS / REACH

HS Code: 2811229000

Port: Shanghai,Guangzhou,Shenzhen

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW

Matting agents are additives used in coatings to reduce gloss and improve surface properties such as scratch resistance,

chemical resistance, and hiding power. They are commonly used in UV-cured coatings to achieve a matte finish. There are

various types of matting agents available, including silica, polyethylene, and wax-based agents.

UV70C is a specific type of Matting Agent that is a wax-based dispersion designed for UV-curable coatings. It offers excellent

scratch resistance and matting efficiency, making it suitable for a wide range of applications, including wood, plastics, and

metal coatings.

Compared to other types of matting agents, UV70C is known for its high efficiency, low viscosity, and ease of use. It is also

compatible with various resin systems, including acrylates, epoxies, and polyurethanes.

Overall, matting agents for UV coatings vary in their properties and performance. When selecting a matting agent, it is essential

to consider factors such as the desired level of matting, substrate, and application method. UV70C is a popular choice for its

efficiency and versatility, but other options may be more suitable depending on the specific requirements of the coating.

1. It has high extinction efficiency and good compatibility with most resins.

2. It can be widely used in low VOC system because of its low oil absorption value and low thixotropy.

3. It is easy to disperse and not easy to settle and agglomerate when it is directly added into the system.

4. Study on unstable foam of coating system.

5. Improve the scratch resistance of the film without affecting the mechanical properties of the film.

6. It can obtain excellent performance and reduce production cost at the same time.

Chemical Data

| Item | SS-U70 |

| Content of sio2(dry basis) %, | ≥99.0 |

| Porosity ml/g | 1.8-2.0 |

| Oil absorption, g/100g , g/100g | 230-270 |

| Particle Size, um(Malvent,D50) | 6-7 |

| Loss on drying(105℃,2Hrs) | ≤5.0 |

| Ignition loss(1000℃,2Hrs) | ≤13.0 |

| Whiteness | ≥90.0 |

| PH(5% Liquor) | 6-7 |

| Surface Treatment | Organic |

Application:

UV floor wood Coatings, UV Plastic Coaitngs, UV Printing Inks.

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Product Categories : Matting Agent > Matting Agent For UV Coatings

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.