Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: WF-100

Brand: SKYIMG

Material: Pvc, Pet, Pp, Polyester

Types Of: Twist Film

Use: Decorative Film

Special Performance: Moisture Proof

Hardness: Soft

Transparency: Translucent

Place Of Origin: China

Usage: Visible Film

Sensitivity: Medium-sensitivity Film

Color Temperature: Daylight Type

Imaging Type: Positive

Color: Milky White: Surface: Glossy

Based Thickness: 100um: Total Thickness: 130um

Transparency: Semi-transparent: Waterproofness: 100% Waterproof

Compatible Printer: Inkjet Printers: Based Material: Polyester(PET)

Packaging: Each roll in the white or yellow corrugated box,6 or 4 boxes together in the yellow corrugated carton,yellow corrugated carton together in the non fumigation pallet

Productivity: 100000Square Meter/Square Mete

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 100000000 Square Meter/Square Meters per Month

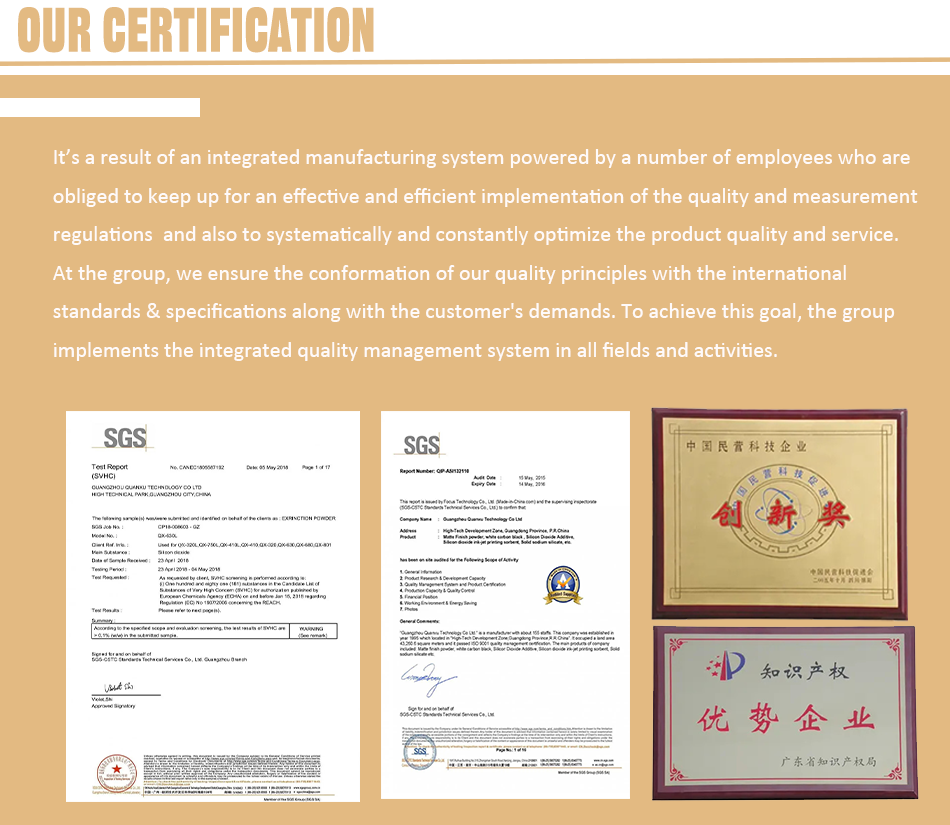

Certificate: SGS

HS Code: 3920690000

Port: Guangzhou,Shenzhen,Shanghai

Payment Type: L/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,CIF,EXW

* Appearance: we can talk about these two substrates' appearance first. Silica appears as white color podwer. And silicone appears as transparent

or mike white solid

* Structure: then we should mention these two substrates' structures. Silica has spongeous structure, and silicone has mutiple holes structures so it has

strong adhesion property which can adsorb different substrates.

* Production method: For producing silica, we should get Silica Powder from natural silicon dioxide by grinding.Then we should use precipitation method

to change silica powder's self chemical parameter. For producing silicone, firstly adding dilute sulfuric acid into water solution of water glass and stewing.

After a while, there is a solid state hydrosilicic acid gel. Then using water to wash the electrolytic ion Na+ and SO42-( Cl-) and dry the solvent, we can get

silicone.

* Usages: silica powder is often used as additive in coating which can provide excellent matte effect and adhesion property. Silicone is often used as dryer

or catalyst.

Yes, silica Matting Agent is really useful in coating. Normally, it is used as additive to add into coating for enhance coating's self properties include adhesion

property, image clarify property, resistance property and etc. What's more, the most important usage of silica matting agent in coating is to make the coating

from mirror state to rough state by create a matte effect. This change can reduce the coating's glossy value and reduce the situation of vision obstruction due

to light reflection.

First you should prepare the exact content of silica matting agent before adding into coating's formulation. Then try to add silica matting agent into the coating

and mix it with the other chemical materials by high speed mixture machines. Then put the mixing solvent under the high temperature enviornment to dry. For details,

follow the specific operation instructions.

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent,PET

Product Categories : Matting Agent For PET Film > Matting Agent For Advertising Film

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.