Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: WF-100

Brand: SKYIMG

Material: Pvc, Pet, Pp, Polyester

Types Of: Twist Film

Use: Decorative Film

Special Performance: Moisture Proof

Hardness: Soft

Transparency: Translucent

Place Of Origin: China

Packaging: Each roll in the white or yellow corrugated box,6 or 4 boxes together in the yellow corrugated carton,yellow corrugated carton together in the non fumigation pallet

Productivity: 100000Square Meter/Square Mete

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 100000000 Square Meter/Square Meters per Month

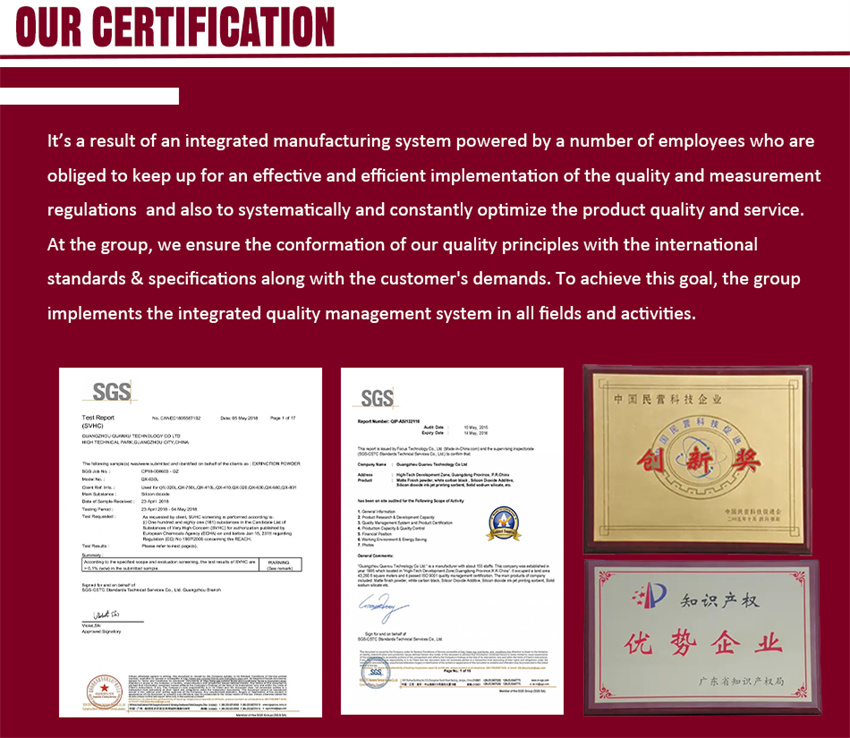

Certificate: SGS

HS Code: 3920690000

Port: G,u,a

Payment Type: L/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,CIF,EXW

What silica Matting Agent's factors will effect the advertising film coating?

WF-100 silica is not the solid state particle. It is considered as spongy structure and it has exact particle size. This particle

size can be changed depend on production guideline.

* Porosity

Silica matting agent with low porosity can adsorb the water but it has worse withstand ability of liquid system. It is suitable

to use in applications that particle strength is essential due to its structure.

Silica matting agent with high porosity just like our produce WF-100 silica matting agent is effective to use as matting agent.

Cause this type silica matting agent can provide more particles in each weight unit. At the same time, the density of this type

silica matting agent is lower. Silica matting agent with these two factors can provide a better thickening effect to added medium.

When silica matting agent with high porosity is adding into advertising film coating, it can help to enhance the coating's clarify

and avoid the situation of discoloration.

* Particle Size

In many applications, the selections of silica matting agent depend on polymers' thickness. Normally, silica matting agent is suitable

to use in composite leather coating and printing ink when its particle size is between 4-6 um. Silica matting agent with 6-8 um particle

size is suitable to use in metal coating. And silica matting agent with 8-14 um particle size is suitable to use in special surface which

needs total matte effect. Silica matting agent with large particle size is easy to disperse and the effect on the viscosity of the system

is minimal. Choosing correct silica matting agent in coating is important to coating's printing clarify, color density and gamut. In this

advertising film coating, WF-100 silica matting agent with particle size that is between 4-6 um is suitable.

* Distribution

WF-100 silica matting agent is easy to disperse and it can be added to coatings alone or with pigments and other additives at any

stage of the manufacturing process.This flexibility makes final gloss adjustments and even post-production corrections possible.

The optimal dispersion depends on the shear rate of the agitator blade and the viscosity of the paint itself. When the desired amount

of silica is added to the batch, the blender should be gently started and then slowly accelerated to the optimal speed for 15-20 minutes

to obtain a uniform gritty free dispersion.

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent PET

Product Categories : Matting Agent For PET Film > Matting Agent For Advertising Film

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.