Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: SL-860

Brand: SKYSIL

Place Of Origin: China

Appearance: Powder

Usage: Leather Auxiliary Agents

Type: Carbon Black

Adsorbent Variety: Silica Gel

Color: White

Counter Type: RAD2105/UV70C

Packaging: 10 kgs/bag, 360 kgs/Pallet, 20 fcl 3.6 Ton With Palletized, 4.5 Ton Without Pallet.

Productivity: 10000 Ton/Year

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 800 Ton/Month

Certificate: SGS/ ASTM / ROHS / REACH

HS Code: 2811229000

Port: Guangzhou,Shenzhen,Shanghai

Payment Type: L/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,CIF,EXW

Description

Silica paint matting agents are widely used in UV roller coatings to achieve a matte finish. These agents are made

from silica particles that are specially treated to improve their dispersibility and compatibility with the coating system.

The main function of silica matting agents is to scatter light and reduce the gloss of the coating. This is achieved by

creating a rough surface on the film, which breaks up the reflection of light and gives the coating a matte appearance.

Silica matting agents are typically added to the coating formulation at a concentration of 5-10% by weight. The exact

dosage will depend on the desired level of gloss reduction and the specific properties of the coating system.

One of the key advantages of silica matting agents is their compatibility with UV-curable coatings. These coatings are

often used in applications where fast curing times and high durability are required, such as automotive and industrial

coatings.

Silica matting agents can also improve the scratch resistance and abrasion resistance of the coating, making it more

durable and long-lasting.

Overall, silica matting agents are an effective and versatile additive for achieving a matte finish in UV roller coatings.

They offer excellent compatibility with the coating system and can improve the performance of the coating in a variety

of ways.

Characters

Lower Viscosity. This silica Matting Agent produce by unique technology and cover with special surface treatment. It

has low oil absorption, good dispersibility, excellent matting efficiency, all of which enables better scratch resistance

and deposition prevention to the film, as well as excellent hand feeling.

Chemical Data

| Item Type | SL-860 | SL-870 |

| Content of sio2(dry basis) %, | ≥99.0 | ≥99.0 |

| Porosity ml/g | 1,8-2.0 | 1.8-2.0 |

| Oil absorption, g/100g , g/100g | 230-270 | 230-270 |

| Particle Size, um(Malvent,D50) | 4-5 | 6-7 |

| Loss on drying(105℃,2Hrs) | ≤5.0 | ≤5.0 |

| Ignition loss(1000℃,2Hrs) | ≤13.0 | ≤13.0 |

| Whiteness | ≥90.0 | ≥90.0 |

| PH(5% Liquor) | 6-7 | 6-7 |

| Surface Treatment | Organic | Organic |

Application

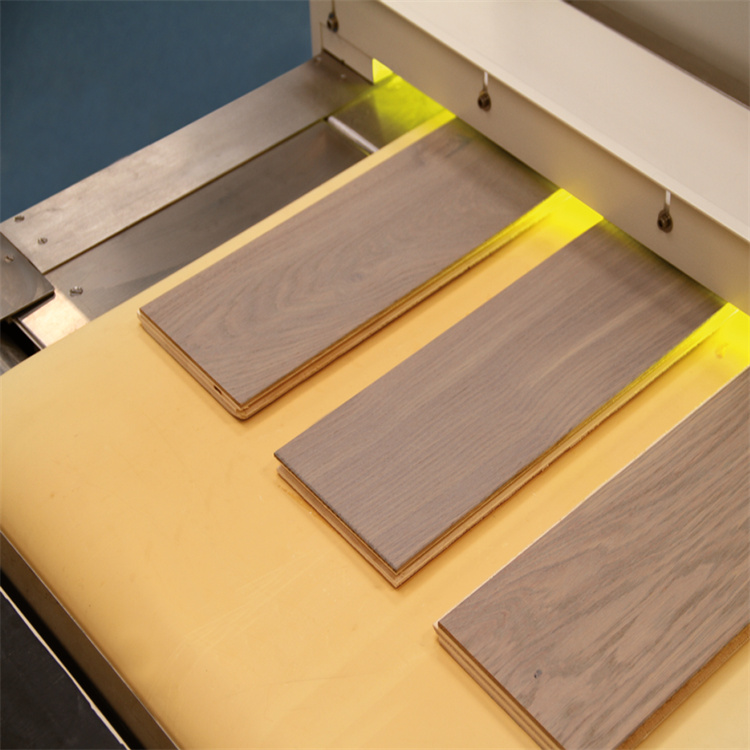

UV curtain coating, roller coating, spraying coating.

UV wood coating, UV floor coating, UV plastic coating,

UV ink.

Matting Agent

Product Categories : Matting Agent > Matting Agent For UV Coatings

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.