Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: HF-610D

Brand: SKYSIL

Classification: Chemical Auxiliary Agent

Place Of Origin: China

Types Of: Carbon Black

Application Field: Electronics Chemicals

Color: White

Appearance: Powder

Counter Type: OK412LC,OK607LC

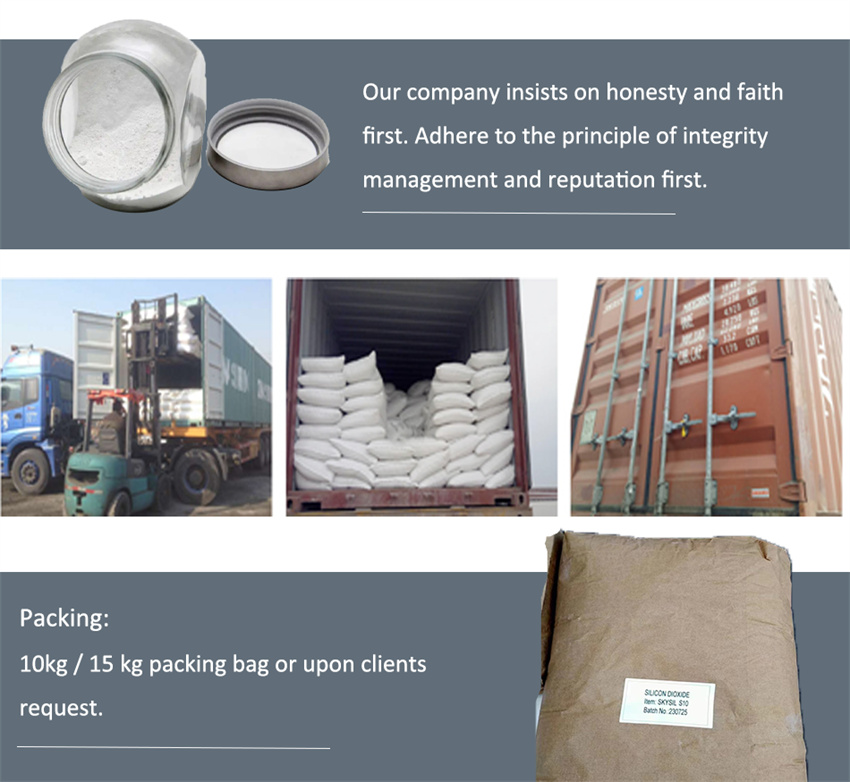

Packaging: 10 KGS / Bag

Productivity: 800 Tons/Year

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 800 Tons / Year

Certificate: ROHS

Port: Nansha,Hongkong

Payment Type: L/C,T/T,Paypal

Incoterm: FOB,CIF,EXW

Why choose silicon dioxide as additive agent in e-coating?

First of all, silicon dioxide is common chemical material in the nature. So its cost is acceptable for the rubber,plastic, paint

manufacturers. Second,it also has a very stable chemical property which is non-toxic, non-corrosive, odorless. Third, it is

not so complex to change the silicon dioxide's self properties to use in various industries. We often use precipitation method

to change its particle size, sulfate content, electrical conductivity and so on.

Making electrophoretic coating should needs four substances. Film-forming substance, pigment, additive and solvent. Adding

silicon dioxide as additive agent in electrophoretic coating can make functions as below.

1. Silicon dioxide can enhance coating's hardeness and scratches resistance which can improve the its durability and using

time.

2. Silicon dioxide can enhance coating's glossy and whiteness.

3. Silicon dioxide can enhance coating's filling and covering properties.This can decrease the coating's transparency which

make the coating covered.

4. Increase the UV resistance of the coating and extend the service life of the coating.

5. Adjust the rheological properties of the coating to make painting easier.

In short, adding white silica powder can improve the performance of the coating and enhance the effect of painting.

| Item | HF-610D | Brand | SKYSIL |

| Content of SiO2,(dry basis) %≥ | 98 | Carbon Content % | 5.5 |

| Porosity ml/g | 2 | Particle Size(Malvent D50),um | 4.0-5.0 |

| Loss on drying (105℃,2Hrs),% | ≤6.0 | PH | 6.0-7.0 |

| Sulfate Content % | ≤0.2 | DOA Absorption g/100g | 230-280 |

| Electrical Conductivity 4%in water, us/cm | ≤200 | Specific surface area(N2) Multipoint, m2/g | 130 |

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Product Categories : Matting Agent > Matting Agent For Electrophoretic Coatings

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.