Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: ZP-100/125/175-R

Brand: SKYIMG

Material: Pvc, Pet, Polyester, Pp

Types Of: Twist Film

Use: Decorative Film

Special Performance: Moisture Proof

Hardness: Soft

Transparency: Translucent

Place Of Origin: China

Sensitivity: Medium-sensitivity Film

Color Temperature: Daylight Type

Color: White: Surface: Matte

Printing Type: Front Print: Dry Time: Dry Instantly

Package: Neutral Export Package: Suitable Printer: Eco Solvent

Compatible Ink: Eco Solvent: Suitable Printer: Solvent Printers

Material: Polyester(PET): Base Thickness: 100/125/175 Microns

Usage: Visible Film

Imaging Type: Reversal Film

Packaging: 10 KGS / Bag

Productivity: 100000Square Meter/Square Mete

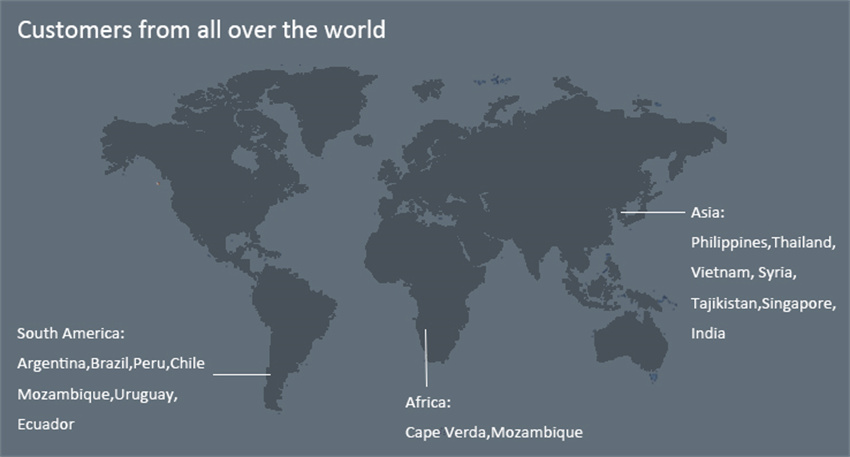

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 100000000 Square Meter/Square Meters per Month

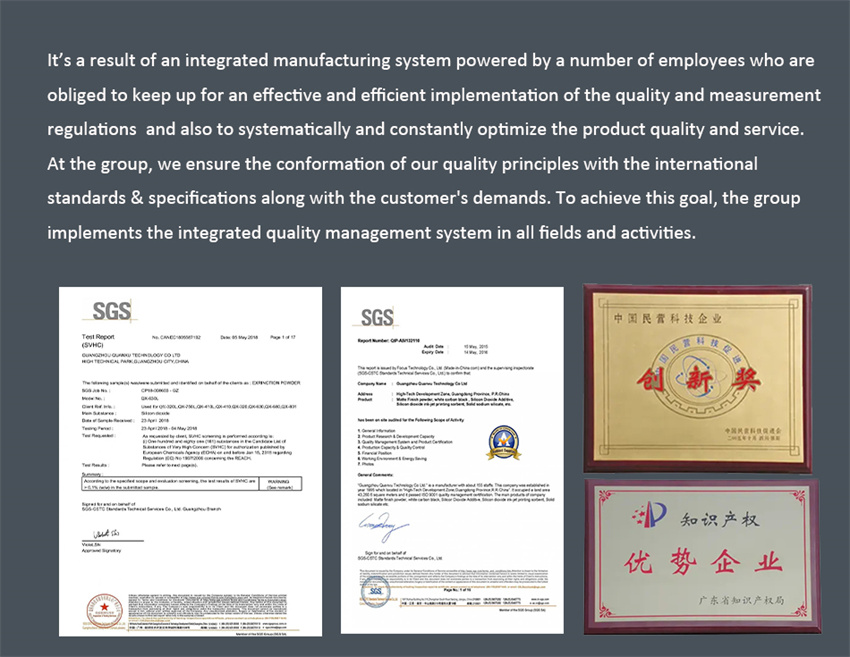

Certificate: SGS

HS Code: 3920690000

Port: Guangzhou,Shenzhen,Shanghai

Payment Type: L/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,CIF,EXW

Matting Agent is used on coating's surface to change the coating's surface properties. It is mainly used to decrease the

surface glossy and it can also provide extra technical property. Basic material like waxes of polyethylene, polypropylene,

carnauba wax, amide and polytetrafluoroethylene (PTFE) can be used as matting agent. But the most common matting

material is silica.

Matting technology is also called as matte effect or matte treatment. It is mainly used for decrease the glossy of coating's

surface to make it looks like matte. In different application industries, different materials of matting technologies might be

different. Below are the common materials that are used in matting technologies.

1.Coating: In industries and in families, using coating with Silica Matting Agent can help to decrease the glossy value. This

type of coating can be applied in furnitures, walls, cars and etc.

2.Powder coating: During the surface treatments of metal, using silica matting agent can achieve the matte effect and this

technology is usually used in outdoor.

3.Grinding material: In the machining process, the use of abrasive (such as sandpaper, grinding wheel, etc.) to grind metal or

other materials to remove the gloss of the surface and achieve the matting effect.

4. Chemical treatment: Changing the materials' surface physical properties by chemical reaction to achieve

matte effect. For example, in glass processing, a specific chemical etching process can be used to make the glass surface

less smooth and reduce reflection.

5. Embossing or texture: Texture is formed on materials such as plastic, leather, and 4. Fabric by pressing or engraving

techniques to reduce gloss and increase visual effect.

6. Coated composite material : Combine a variety of materials, such as coating a layer of matting effect on a metal substrate,

and control the gloss of the final product by adjusting the composition and thickness of the coating.

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Product Categories : Matting Agent For PET Film > Matting Agent For Advertising Film

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.