Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: QX-520

Brand: SKYIMG

Place Of Origin: China

Kind: Fixing Agent

Appearance: Liquid

Application: Post-Processing Auxiliary

Packaging: 60KG or 130 KG net in plastic drum

Productivity: 10000KG/Year

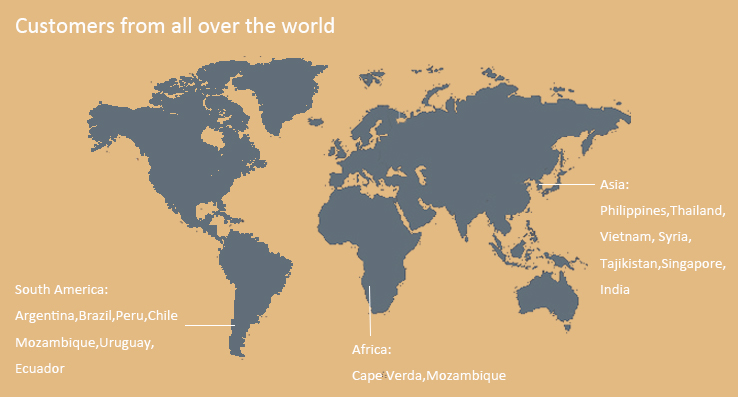

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 800KG/Month

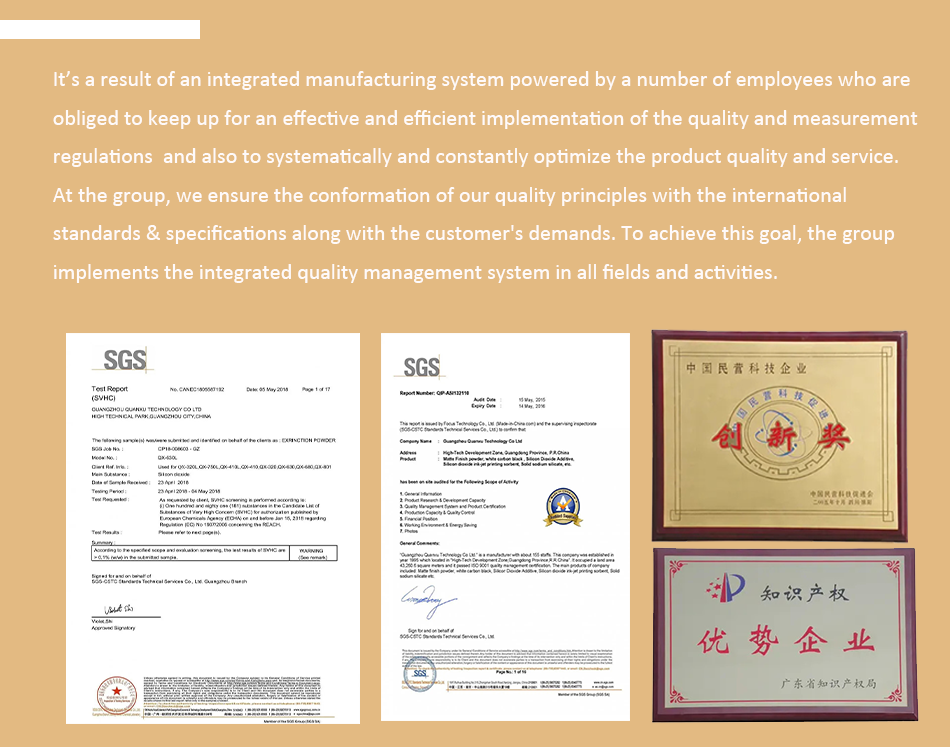

Certificate: ISO/SGS

HS Code: 390690

Port: Shanghai,Guangzhou,Shenzhen

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW

General Description

Reactive dyes printing thickener is a type of Thickening Agent used in the textile industry for printing with reactive dyes.

Reactive dyes are a type of dye that chemically reacts with the fibers of the fabric, resulting in a permanent bond. This

type of dye is commonly used for printing on natural fibers such as cotton, linen, and silk.

The reactive dyes printing thickener is used to increase the viscosity of the printing paste, allowing for better control of

the dye application and preventing bleeding or spreading of the dye on the fabric. It also helps to improve the sharpness

and definition of the printed design.

Some common applications of reactive dyes printing thickener include:

1. Textile printing: Reactive dyes printing thickener is widely used in textile printing processes to create intricate and vibrant

designs on fabrics. It helps to ensure that the dyes are evenly distributed and adhere to the fabric fibers, resulting in long-lasting

and colorfast prints.

2. Screen printing: Reactive dyes printing thickener is commonly used in screen printing, which is a popular method for printing on textiles. The thickener helps to prevent the dyes from seeping through the screen and spreading on the fabric, resulting in clean

and crisp prints.

3. Block printing: Reactive dyes printing thickener is also used in block printing, a traditional method of printing where a carved

block is used to apply the dye onto the fabric. The thickener helps to control the flow of the dye and prevent it from spreading

outside the desired design area.

4. Digital printing: Reactive dyes printing thickener is used in digital printing processes, where designs are printed directly onto

the fabric using specialized printers. The thickener helps to ensure that the dyes are properly absorbed by the fabric and do not

bleed or spread during the printing process.

Overall, reactive dyes printing thickener plays a crucial role in achieving high-quality and durable prints with reactive dyes. It

helps to improve the printing process by increasing the viscosity of the dye paste, resulting in better control and definition of the

printed design.

| Item | QX-520 | PH Value | 6~7 |

| Composition | High molecular acrylic polymerss | Appearance | Light yellow viscous paste |

| Ionic Property | Anionic | Solid Content | 70±2% |

Remarks:

I.Dosage of stock paste is adjustable subject to dosage of dyestuff and printing machine.

II.Dosage of urea is subject to the type of fabrics and printing processes.

III.Overall dosage,including printing grade sodium alginate is 4-4.5% on rotary screen printing machine

and 4.5-5% on flatbed printing machine.

Washing processes:

I. Cold water wash with 1g/L glacial acetic acid for removal of printing paste residuals.

II.Hot water Wash with 2g/L anti-staining soaping agent under 80-100℃

III.Cold water wash

Package

60KG or 130 KG net in plastic drum

Storage

Keep in cool, ventilated place.

Notes

The product is environmental friendly product, and is not subject to IATA DGR. Please follow the

general rules and regulations for common chemicals during transportation and storage.

When the temperature getting cold, thickener would become thicker, but would not affect printing

performance.

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Product Categories : Thickening Agent > Reactive Dyes Thickening Agent

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.