Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: M46

Brand: SKYSIL

Place Of Origin: China

Model No.: M46

Suitable Industry: Matte Paper Coatings

Certificate: SGS/ISO9001

Productivity: 100000 Ton/Year

Brand Name: SKYSIL

Packaging: 10 kgs/BAG, 40 kgs/Pallet, 4 Ton/10 pallet.

Productivity: 800 Ton/Month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 800 Ton/Month

Certificate: ROHS

Port: Guangzhou,Shenzhen,Shanghai

Payment Type: L/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,CIF,EXW

Why can we use M46 silicon dioxide as Matting Agent in matte coating?

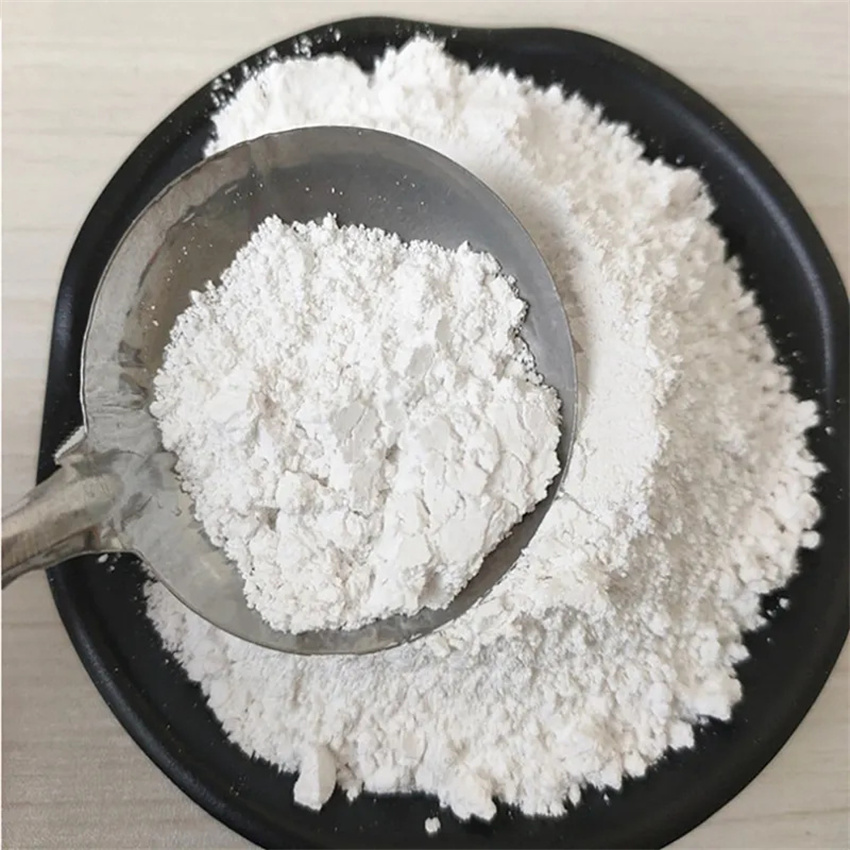

Silicon dioxide is also called as silica powder, it is one of the chemical materials of matte paper coating. It can enhance

the papers' quality and appearance.

When adding silicon dioxide powder into paper formulation, it can help to enhance the papers' printing quality and ink

adhesive property. It can produce a clear and attractive images.

* High Transparency- this type silica dioxide has such a high transparency which means that it can work very well on the

matte paper coating.When painting the coating on the white paper's surface, you will not notice the silica particles. When

you are touching the matte paper after it was painted, you will feel the smooth hand-feeling.

* Amazing Adhesion Property - As we all know that silica dioxide is a common material in the chemical market. It is made up

by silicon atom and the oxygen atom. Expect for the adding into matte paper coating to create the matte effect, it also has the

amazing adhesion property in the coatings. This can extend the coatings' using time which can enhance the suspension

performance.Silica matting agent is used in various surface to create matte effect. This silica matting agent is produced by

precipitated technology.

Using this silica matting agent's main function is to decrease the surface glossiness which can create matte surface. It is ideal

to use in paintings,coatings, ink and other appplications.

Silica matting agent will become transparent when it is added into the coatings. This means that adding silica matting agent

into the coatings will not change the coatings' clarify and transperency. This ability is very important in keeping the original

apperance of the coatings like transparent coatings or plastic films.

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Product Categories : Matting Agent > Matting Agent For Matte Paper Coatings

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.