Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: H-903

Brand: SKYSIL

Model No.: H-903

Suitable Industry: Matte Paper Coatings

Certificate: SGS/ISO9001

Productivity: 100000 Ton/Year

Brand Name: SKYSIL

Place Of Origin: China

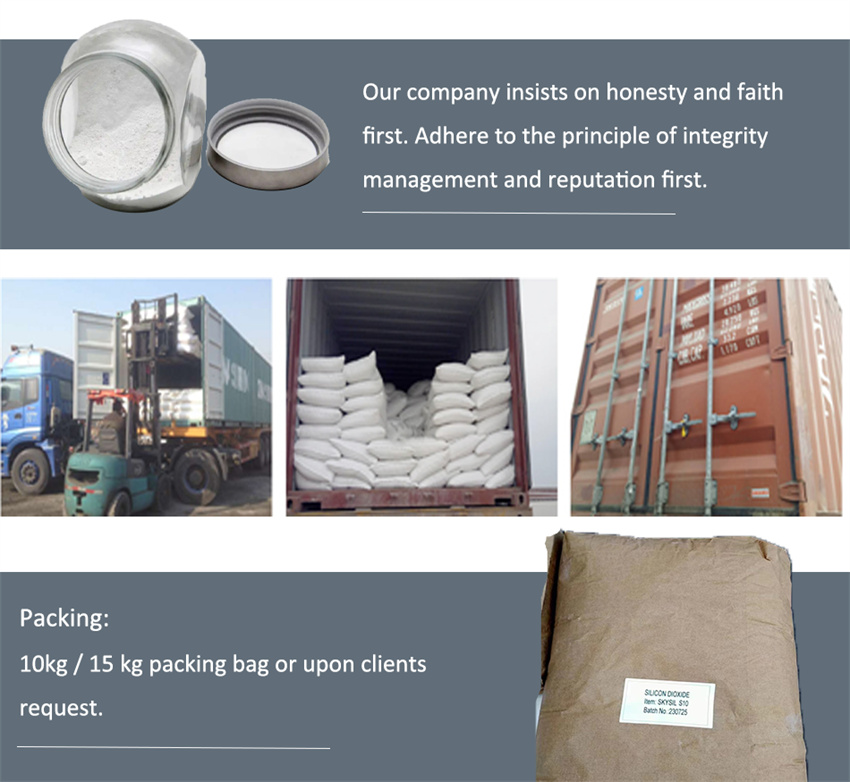

Packaging: 10 kgs/BAG, 40 kgs/Pallet, 4 Ton/10 pallet.

Productivity: 800 Ton/Month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 800 Ton/Month

Certificate: ROHS

Port: Guangzhou,Shenzhen,Shanghai

Payment Type: L/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,CIF,EXW

Characteristics

Silica Matting Agent is commonly used in the production of matte paper coatings. It is a fine particle material that is added

to the coating formulation to create a rough surface texture, resulting in a matte appearance.

The main purpose of using silica matting agent in matte paper coatings is to reduce the glossiness and shine of the paper

surface. This is achieved by scattering and diffusing light, which creates a soft, non-reflective finish.

Silica matting agents are typically made of amorphous silica particles with a specific particle size distribution. The particle

size and shape of the silica particles play a crucial role in determining the level of matting effect achieved.

Matte paper coating can help to improve the durability and longevity of printed materials. The coating acts as a protective

layer, guarding against smudges, fingerprints, and scratches. This makes matte coated paper a popular choice for products

such as brochures, business cards, postcards, and book covers.

Matting agents are additives used in matte paper coatings to create a smooth, non-reflective surface. These agents work by

reducing the gloss and shine of the coating, resulting in a matte finish. Here are some commonly used matting agents for matte

paper coatings:

1. Silica: Silica is a common matting agent used in matte paper coatings. It is available in different particle sizes and can be

added to the coating formulation to achieve the desired level of matting.

2. Polyethylene Wax: Polyethylene wax is another matting agent used in matte paper coatings. It helps to reduce the gloss and

provide a smooth, matte finish to the paper surface.

3. Matting Resins: Matting resins are specially designed polymers that can be added to paper coatings to create a matte

appearance. These resins typically have a high molecular weight and low solubility, which helps in reducing the gloss of the

coating.

4. Organic Matting Agents: Organic matting agents, such as synthetic polymers or natural materials like starch, can also be used

in matte paper coatings. These agents work by scattering light and reducing the reflection, resulting in a matte finish.

5. Matting Agents Blends: Sometimes, a combination of different matting agents is used to achieve the desired level of matting in

matte paper coatings. This can help in fine-tuning the matte effect and improving the overall appearance of the coated paper.

It is important to note that the choice of matting agent depends on various factors, including the desired level of matting, coating

formulation, and printing process. Therefore, it is recommended to consult with a coating specialist or supplier to select the most

suitable matting agent for your specific application.

USING TIPS:

* Recommend dosage is 3%-8%. (Please adjust the dosage according to the actual product.) * As different formulations and conditions, suggest the user to test and make sure the dosage before using.

| Item | H-903 | Brand | SKYSIL |

| Content of sio2(dry basis) % | ≥99.0 | Porosity ml/g | 1.8-2.0 |

| Particle Size(Malvent D50),um | 6.0-7.0 | Whiteness | ≥90.0 |

| Loss on drying(105℃,2Hrs) | ≤5.0 | PH | 7.0-8.0 |

| Ignition Loss(1000℃,2Hrs),% | ≤6.0 | Oil Absorption g/100g | 260-300 |

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Product Categories : Matting Agent > Matting Agent For Matte Paper Coatings

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.