Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: SL-715

Brand: SKYSIL

Classification: Chemical Auxiliary Agent

Place Of Origin: China

Applications: Industrial Coatings

Appearance: White Color Powder

HS Code: 281122

Types Of: Carbon Black

Application Field: Coating Auxiliary Agents

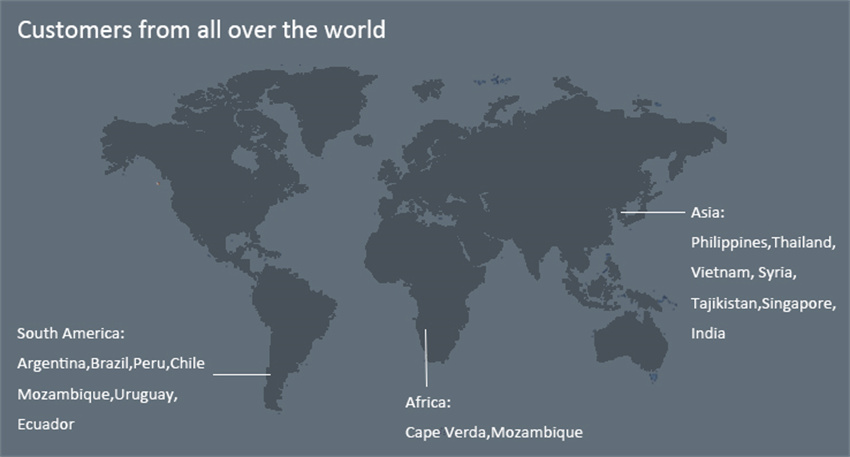

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 10000 Tons/Year

Port: Nansha,Shenzhen

Payment Type: L/C,T/T,Paypal

Incoterm: FOB,CFR,CIF,EXW

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

* Highly dispersible matting powder has a lot to do with its surface area

Like traditional matting powder, when the surface area of highly dispersible matting powder is higher, the reinforcement

performance is also better. When the surface area is larger, the reinforcement performance is better, but the processing

performance is poor. The reinforcing performance of high-dispersibility matting powder with the same surface area is better

than that of traditional matting powder.

Matting powder with high surface area has a higher concentration of silanol groups. The free silanol groups will interact strongly

with the accelerator, which will lead to a decrease in the vulcanization rate of the rubber compound. When the BET surface area

of the matting powder exceeds 200㎡·g, the vulcanization rate will be too low. Therefore, the BET surface area of high-dispersibility

matting powder generally does not exceed 200㎡·g.

When the structure of the matting powder is higher, the dispersibility is better and the vulcanization rate is also higher. The phenomenon

of better dispersibility when the structure is higher can be explained as follows: matting powder with high structure has more pores,

and the polymer will penetrate into the pores at the beginning of mixing. Then, when the agglomerates are subjected to the mixing

shear force and are broken into aggregates, they will be better dispersed in the polymer. However, traditional matting powder with

low structure is pressed very hard at the beginning of mixing a

SL-715 Silica Matting Agent is synthetic amorphous silica appearing as white powder.

CAS Number(SILICON DIOXID

Product Categories : Matting Agent > Matting Agent For Industrial Coatings

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.