Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: H-305

Brand: SKYSIL

Place Of Origin: China

Application Field: Furniture Paint, Appliance Paint, Boat Paint, Building Coating

Instructions: Spray

Status: Powder Coating

Color: White

Appearance: Powder

Certification: ISO9001

Counter For: OK412,C807

Packaging: 10KGS / BAG

Productivity: 800 Tons / Year

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 800 Tons/Year

Certificate: ROHS

Port: Nansha,Hongkong

Payment Type: L/C,T/T,Paypal

Incoterm: FOB,CIF,EXW

What factors will effect precipitated silica?

1. PH value

The acidity and alkalinity of silica have a great influence on the vulcanization of rubber. Acidic silica delays the vulcanization of rubber, while

alkaline silica promotes vulcanization. However, too high alkalinity is not good for reinforcement. Silica with a slightly acidic pH is beneficial to

the tensile and wear resistance of rubber and products. Therefore, the pH value of precipitated silica for silicone rubber is generally 6-8, which

is close to neutral.

2. Surface modification

The surface modification of silica refers to adding a coupling agent to silica to achieve its hydrophobicity. After adding the coupling agent, the

CH3O-(methoxy) at one end of the coupling agent easily reacts with the silanol group on the surface layer of silica, and the other end reacts with

the rubber molecule, that is, the coupling agent "bridges" between silica and silicone rubber. There are many ways to modify the surface of silica.

The most common one is to use a silane coupling agent (such as Si-69) for treatment.

Using silica Matting Agent into economic coating

Introducing our latest breakthrough in the realm of paint additives - the good suspension silica matting agent for economical paint. Designed to

elevate the performance and quality of economical paint, this cutting-edge silica matting agent boasts superior suspension properties, ensuring

a smooth and even dispersion of pigments in the paint formulation.

With its exceptional suspension capability, our Good Suspension Silica Matting Agent guarantees a homogeneous mixture, preventing the

occurrence of sedimentation or clumping. This not only saves valuable time for paint manufacturers during the production process but also enhances

the overall consistency and stability of the paint, resulting in a more uniform finish on application.

Furthermore, this revolutionary matting agent significantly improves the leveling and flow characteristics of the paint, allowing for effortless application

and smooth brush strokes. The uniform dispersion of pigments ensures even color distribution, eliminating any potential streaks or uneven patches on

the painted surface. This results in a professional-grade finish that is sure to impress even the most discerning customers.

In addition to its exceptional suspension and leveling properties, the Good Suspension Silica Matting Agent also offers excellent matting efficiency. This

means that it effectively reduces the glossiness of paint, providing a matt finish that is both aesthetically pleasing and on-trend. Whether used for interior

or exterior applications, this matting agent adds a touch of elegance and sophistication to any painted surface.

Moreover, our Good Suspension Silica Matting Agent is formulated with a keen focus on environmental sustainability. It is free from harmful or toxic

substances, making it a safe choice for both the environment and the end-users. By choosing our matting agent, you can rest assured that you are contributing

to a cleaner and greener future.

In conclusion, our Good Suspension Silica Matting Agent For Economical Paint is a game-changer in the paint industry. With its superior suspension properties,

it ensures a smooth and even dispersion of pigments, resulting in a consistent and professional finish. Its excellent leveling, flow, and matting efficiency make

it a must-have for any paint manufacturer or professional painter.

Choose our matting agent and experience the transformative power it brings to your economical paint formulations.

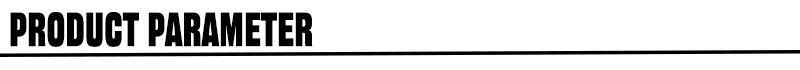

The following specification parameters will be stated on our Certificate of Analysis.

| Item Type | H-305 |

| Content of sio2(dry basis) % | ≥98.5 |

| Porosity ml/g | 1.2-1.4 |

| Oil Absorption g/100g | 270-320 |

| Particle Size(Malvent,D50),um | 5.5-6.0 |

| Loss on drying(105℃,2Hrs) | ≤5.0 |

| Ignition loss(1000℃,2Hrs) | ≤6.0 |

| Whiteness | ≥90.0 |

| PH(5% Liquor) | 6-7 |

| Surface treatment | None |

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Product Categories : Matting Agent > Matting Agent For Economic Coatings

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.