Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: SKYELEC

Brand: SKYELEC

Place Of Origin: China

Status: Used

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc, Engine, Pressure Vessel, Gear, Pump

Warranty Period: 1 Year

Core Selling Point: High Productivity

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Applicable Industry: Construction Works, Energy &Amp; Mining

Packaging: Cardboard Box / Cardboard Box + Wooden Fram

Productivity: 1000 Unit/Units per Month Fluo

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 10000000 Pieces/Year

Certificate: ISO9001/SGS

HS Code: 8516909000

Port: Guangzhou,Shenzhen,Shanghai

Payment Type: L/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT

Introduction:

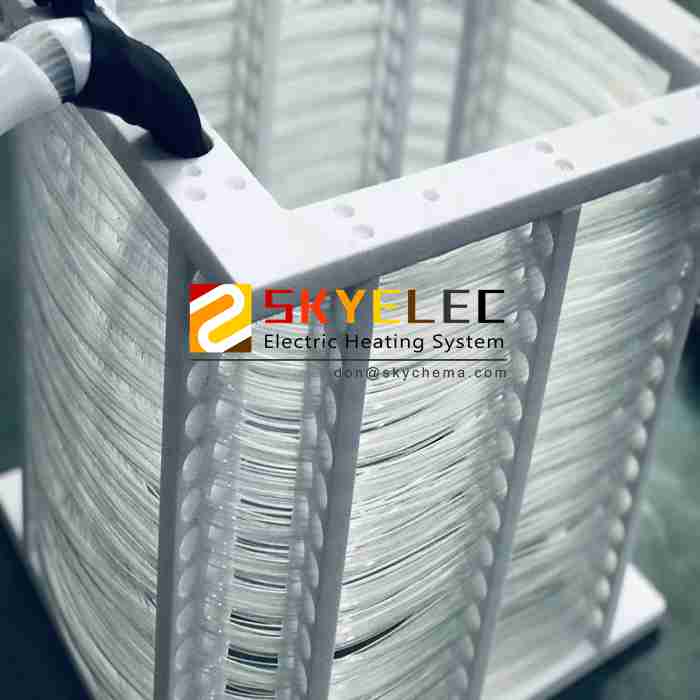

PTFE titanium tube coaxial plate heat exchanger for cooling/heating water, PTFE impregnated graphite heat exchanger.

Engineered specifically for your heating or cooling application.

A titanium coated heat exchanger is a type of heat exchanger that has a titanium coating on its surface. This coating provides

various benefits, especially for applications in heating and cooling systems.

One major advantage of a titanium coating is its corrosion resistance. Titanium is highly resistant to corrosion, making it suitable

for use in environments with aggressive fluids or chemicals. This makes titanium coated heat exchangers ideal for applications in saltwater or corrosive environments.

Another benefit of a titanium coating is its high heat transfer efficiency. Titanium has excellent thermal conductivity, allowing for

efficient heat transfer between the hot and cold fluids. This results in improved heating and cooling performance and reduced

energy consumption.

Furthermore, titanium coatings also provide enhanced durability and longevity to heat exchangers. The coating acts as a protective

layer against wear, erosion, and fouling, extending the lifespan of the heat exchanger and reducing maintenance requirements.

Titanium coated heat exchangers are commonly used in various industries, including chemical processing, oil and gas, marine, and HVAC systems. They are particularly suitable for applications where corrosion resistance, heat transfer efficiency, and durability are essential.

In summary, a titanium coated heat exchanger offers corrosion resistance, high heat transfer efficiency, and improved durability.

These features make it a reliable choice for heating and cooling applications in various industries.

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Product Categories : Electric Heater > Coil & Heat Exchangers

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.