Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: SL-610

Brand: SKYSIL

Place Of Origin: China

Main Ingredient: Acrylic, Epoxy, Nitrocellulose, Polyurethane

Application Field: Appliance Paint, Plastic Coating, Furniture Paint, Paper Coating, Building Coating, Car Paint

Status: Powder Coating

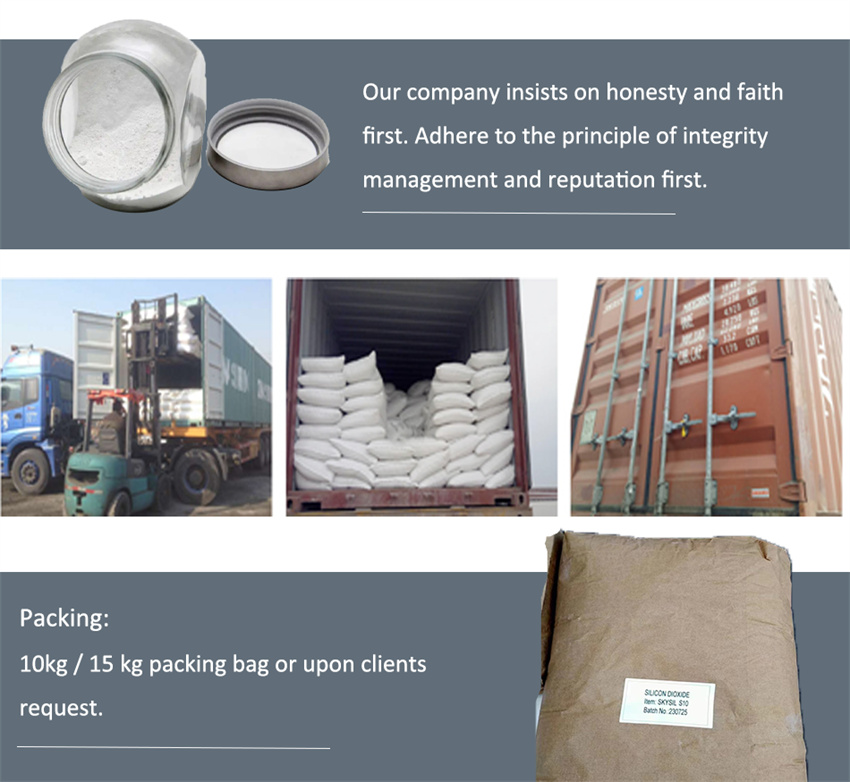

Packaging: 10 kgs/bag, 360 kgs/Pallet, 20 fcl 3.6 Ton With Palletized, 4.5 Ton Without Pallet.

Productivity: 10000 Ton/Year

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 800 Ton/Month

Certificate: SGS/ROHS/REACH

HS Code: 281122

Port: Guangzhou,Shenzhen,Shanghai

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW

Silica white powder is often used as a functional filler in water-based coatings. It is a type of amorphous silica that has a

high surface area and low oil absorption, making it ideal for improving the properties of coatings.

The addition of silica white powder to water-based coatings can provide several benefits, including:

1. Improved durability and scratch resistance: Silica acts as a reinforcing agent, enhancing the mechanical strength and

hardness of the coating. This can help protect the coated surface from scratches, abrasion, and wear.

2. Enhanced hiding power: Silica white powder has excellent hiding power, which means it can improve the opacity and

coverage of the coating. This is particularly important when coating surfaces with different colors or textures.

3. Increased surface smoothness: The fine particle size of silica white powder helps to fill in surface imperfections, resulting

in a smoother finish. This can improve the appearance and feel of the coated surface.

4. Anti-settling and anti-sagging properties: Silica white powder has a high thixotropic effect, which means it thickens the

coating when at rest but thins out when subjected to shear. This helps prevent settling of pigments and fillers during storage

and application, as well as reducing sagging on vertical surfaces.

5. Improved matting effect: Silica white powder can be used to create a matte or satin finish in water-based coatings. By

controlling the particle size and concentration of the silica, the gloss level of the coating can be adjusted to the desired level.

Overall, the addition of silica white powder to water-based coatings can enhance their performance and appearance, making

them more durable, smooth, and aesthetically pleasing.

USING TIPS:

* Recommend dosage is 3%-8%. (Please adjust the dosage according to the actual product.)

* As different formulations and conditions, suggest the user to test and make sure the dosage before using.

| Item | SL-610 | Brand | SKYSIL |

| Content of SiO2,(dry basis) %≥ | ≥ 98 | Whiteness | ≥ 90 |

| Porosity ml/g | 1.8-2.0 | Particle Size(Malvent),um | 4.0-5.0 |

| Loss on drying (105℃,2Hrs),% | ≤6.0 | PH | 6.0-7.0 |

| Ignition Loss(1000℃,2Hrs),% | ≤10.0 | DOA Absorption g/100g | 260-320 |

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Product Categories : Matting Agent > Matting Agent For Water Based Coatings

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.