Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: SL-715

Brand: SKYSIL

Place Of Origin: China

Main Ingredient: Acrylic, Epoxy, Nitrocellulose, Polyurethane

Application Field: Appliance Paint, Furniture Paint, Electrical Insulating Varnish, Plastic Coating, Paper Coating

Instructions: Brush

Status: Powder Coating

Productivity: 100000 Ton/Year

Certificate: SGS/ISO9001

Brand Name: SKYSIL

Model No.: SL-715

Suitable Industry: Plastic Coating

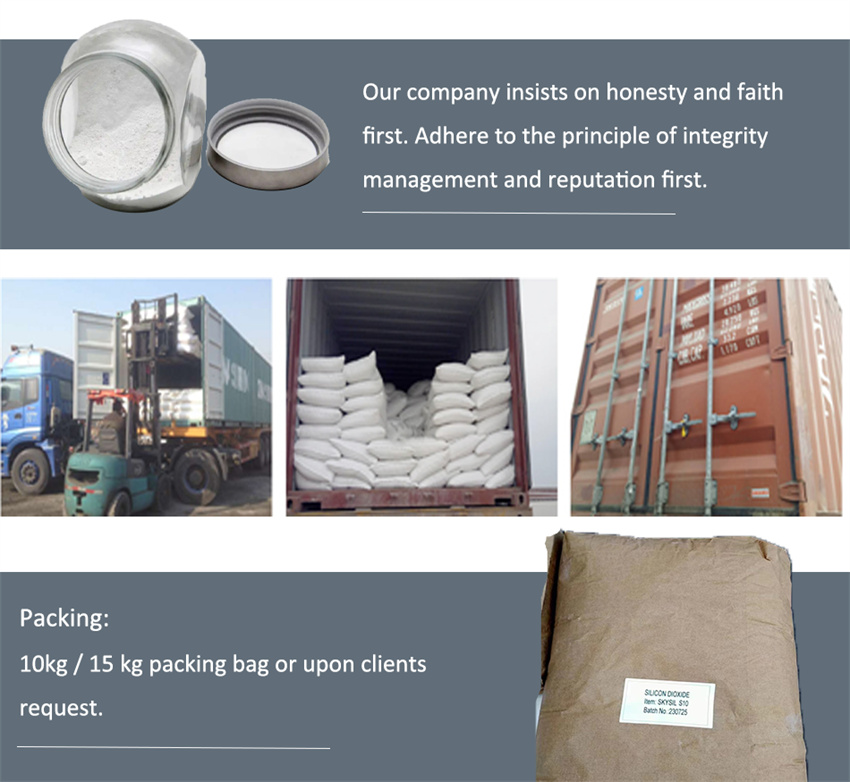

Packaging: 10 kgs/bag, 360 kgs/Pallet, 20 fcl 3.6 Ton With Palletized, 4.5 Ton Without Pallet.

Productivity: 800 Ton/Month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 800 Ton/Month

Certificate: SGS

Port: Shenzhen,Guangzhou,Shanghai

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW

Add pigments or fillers to the paint and evenly distribute them in the coating to form a slightly rough surface. The larger the

particles on the surface, the lower the gloss. Sometimes precipitated calcium carbonate or talc is used in the production of

matte paint. The amount is large, and often exceeds the physical properties, resulting in stratification and hard precipitation.

The use of matting agents can avoid the critical pigment volume concentration of the paint film to produce matte coatings.

Commonly used organic matting agents and inorganic matting agents are mainly silica matting agents, whose chemical

composition is silica, and the surface is divided into organically treated and untreated. The following will introduce the application

of silica matting agents in coatings.

1. Pyrolytic silica Matting Agent: made of ground quartz sand (powder), there are many impurities, the main component is silica, it

cannot be called silica, and it has no matting performance. It is only used as a filler for coatings, and has no matting effect. The silica

coating used as a matting agent is mainly synthetic silica, which is divided into Fumed Silica and precipitated silica, and the microstructure

is amorphous or glassy.

Precipitated silica is made of quartz sand as the main raw material, sodium carbonate or sodium hydroxide and its temperature react in the

furnace, and then pass through the melting treatment system. Fumed silica is made by hydrolyzing silicon tetrachloride in a hydrogen-oxygen

flame. Compared with natural silica, silica has high purity, high inertness, and UV resistance. 1.46 is the refractive index of amorphous silica,

which is similar to the refractive index of many resins in the coating industry. Therefore, amorphous silica with good optical properties can be

used as a matting agent in coatings.

2. Matting mechanism of carbon black and silica matting agent: The mirror film of the varnish coating without matting agent is in a leveling state.

When light reaches the surface of the film mirror, the incident light is partially absorbed and partially reflected, and the part of the film presents

gloss. The film contains silica matting agent, which is evenly distributed in the film of silica particles to form a slightly rough surface.

It can be clearly seen from the cross-sectional scanning electron micrograph of the film that the matting agent particles are evenly distributed in

the film, and when the incident light reaches the uneven surface of the film, it is diffusely reflected, which is scattered to produce a low gloss and

matte appearance. High porosity, optimal particle size distribution and suitable surface treatment of silica matting agent can have a good matting

effect.

Tips:

* Before you use it, please test and make sure the dosage before using according different formulations and conditions.

* Recommended dosage is 3% -5%.

| Item | SL-715 | Brand | SKYSIL |

| Content of SiO2,(dry basis) %≥ | 99 | Whiteness | ≥90.0 |

| Porosity ml/g | 1.8-2.0 | Particle Size(Malvent),um | 9.0-10 |

| Loss on drying (105℃,2Hrs),% | ≤5.0 | PH | 6.0-7.0 |

| Ignition Loss(1000℃,2Hrs),% | ≤7.0 | Oil Absorption g/100g | 280-320 |

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Product Categories : Matting Agent > Matting Agent For Plastic Coatings

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.