Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: QX-406

Brand: SKYIMG

Place Of Origin: China

Main Ingredient: Acrylic, Epoxy, Nitrocellulose, Polyurethane

Application Field: Appliance Paint, Furniture Paint, Paper Coating, Plastic Coating, Car Paint

Instructions: Spray, Brush

Status: Powder Coating

Grade: Industrial Grade

Color: White

Material: Aluminium Oxide (Al2O3)

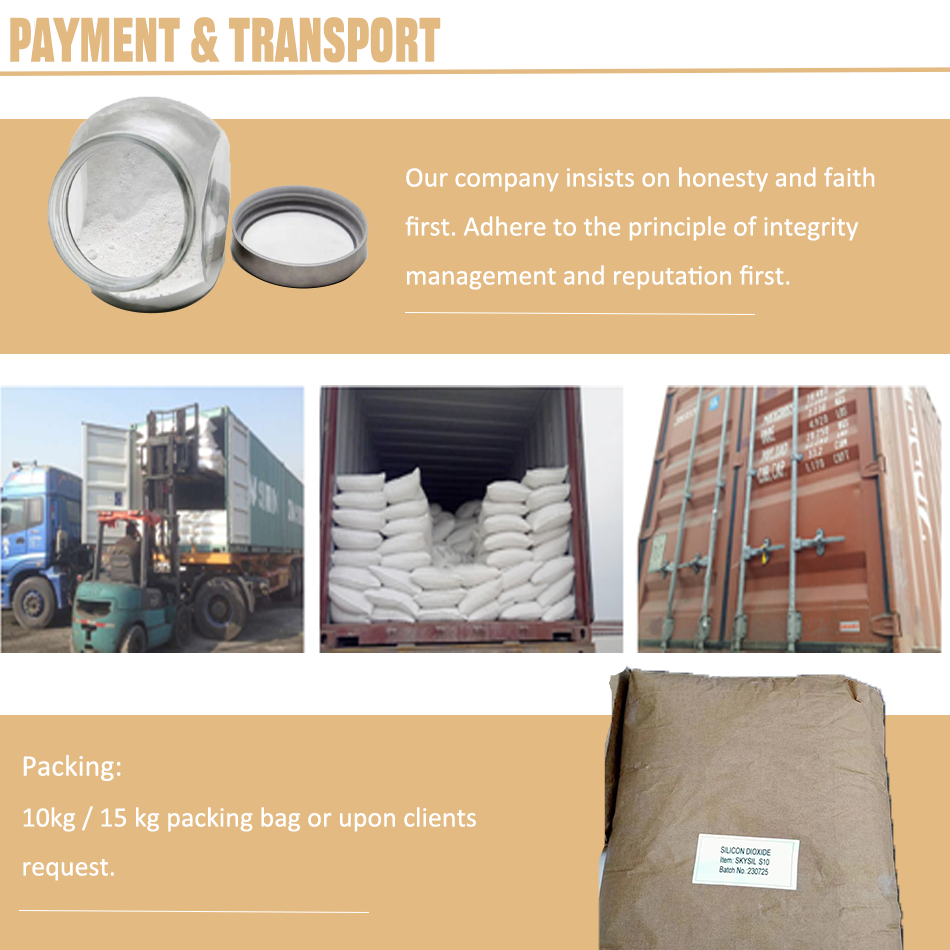

Packaging: 25kgs/Bag

Productivity: 10000 Ton/Month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 10000 Ton/Month

Certificate: ROHS

Port: Guangzhou,Shenzhen,Shanghai

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW

Nano-alumina is an important inorganic pigment. At present, it has been widely used in color inkjet printing paper coatings

due to its large surface area, low density, high whiteness, soft structure, and good printing performance. Nano-pigments refer

to pigments with a particle size of 1~100 nm. The gloss and ink density of coated paper with alumina as pigment are higher

than those of other pigment-coated papers. This shows that the use of nano-alumina pigments in coating can greatly improve

the grade and market competitiveness of coated paper.

Problems in use The biggest problem with nano-alumina pigments is the stable dispersion problem in the coating. This is because

the specific surface area and surface tension of nanoparticles are large, and they are easily adsorbed and agglomerated. In

water-based coatings, the high surface energy and specific surface energy of nano-alumina pigments will strongly adsorb water

and other media and react to form R-OH structures, which increases the interaction between nano-pigments and their surface activity;

and R-OH is prone to polymerization or the formation of new connectors, which makes nano-pigments and slurries more likely to agglomerate,

thereby affecting their dispersibility.

| Item | Paremeters |

| Type | QX-406 |

| Chemical composition | AlOOH.xH2O |

| Appearance | White Powder |

| Crystallites Size(nm) | 10~20 |

| Loss On Ignition | 20% max |

| Specific Surface Area(m2/g) | 140±10 |

| Pore Volume(cm3/g) | 0.81±0.1 |

| Mean Pore Diameter(nm) | 25±1 |

| Mean Pore Diameter(nm) | 0.4~0.6 |

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Product Categories : Matting Agent > Matting Agent For Inkjet Receptive Coating For Cast Coated Paper

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.