Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: MS-730

Brand: SKYSIL

Place Of Origin: China

Application Field: Coating Pigment, Ink Pigments, Plastic &Amp; Rubber Pigment, Leather Pigments

Packaging: 10 kg/bag, Kraft Paper Bag

Productivity: 1000 Ton per Month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 10000 Ton per Year

Certificate: SGS

HS Code: 2811229000

Port: Guangzhou,Shenzhen,Shanghai

Payment Type: L/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,CIF,EXW

Feature

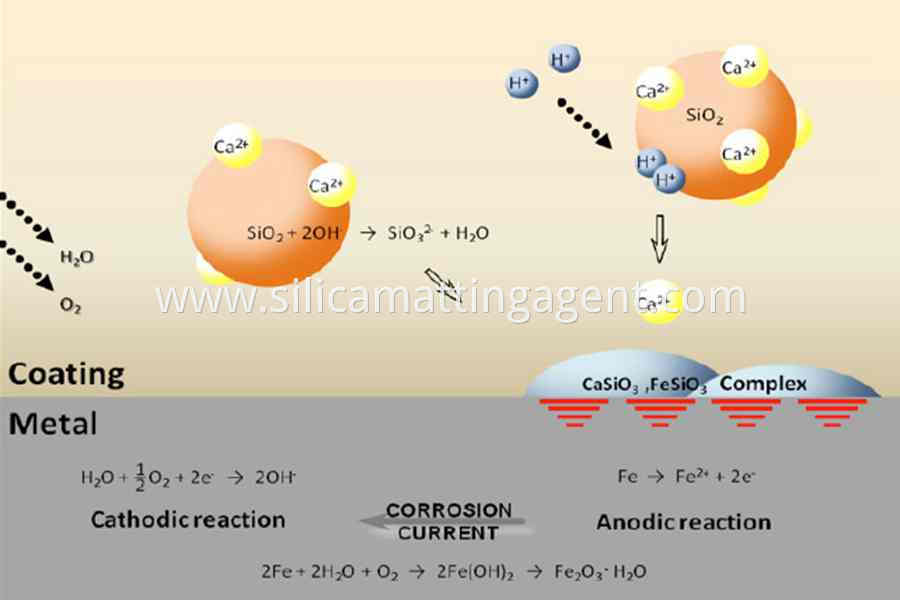

Silica anticorrosion pigment is a type of additive that is used in boat and container coatings to provide protection against

corrosion. This pigment is made from silica particles, which have excellent anti-corrosive properties due to their high hardness

and chemical inertness.

When added to coatings, silica anticorrosion pigment forms a barrier on the surface of the substrate, preventing moisture and

oxygen from reaching the metal underneath. This helps to inhibit the formation of rust and other forms of corrosion, extending

the lifespan of the coating and the substrate.

In addition to its anti-corrosive properties, silica pigment also provides other benefits such as improved adhesion, abrasion

resistance, and UV protection. It is commonly used in marine and industrial coatings for boats, containers, pipelines, and other

metal structures that are exposed to harsh environmental conditions.

Overall, silica anticorrosion pigment is an essential ingredient in boat and container coatings to ensure long-lasting protection

against corrosion and maintain the structural integrity of the substrate.

Technical Index

| Items | Specifications |

| SiO2 Content (based on Ignited Substance, %) | 99 |

| Porosity (ml/g)≥ | 0.3-0.5 |

| Oil Absorption (DBP, g/100g) | 70-120 |

| Particle Size Laser diffraction, d50(μm) | 2.7-3.2 |

| Loss on drying (105℃ %≤) | <5 |

| Loss on Ignition (1000℃%≤) | <10 |

| Whiteness %≥ | 95 |

| PH Value (5% in water) | 5.5-7.5 |

Main features:

1. High anti-rust function.

2. Do not easy to delaminate.

3. To make solvent based types of anti-rust paint and primer have a good stability.

4. Also can be used in water base anti-rust paint.

5. Easily dispersed in the process of making the paints.

6. Completely replace zinc phosphate in paint making.

7. Even less dosage than zinc phosphate.

8. High performance for both cost and anti-rust characters.

User friendly

It is easy to operate the paint when using our pigments by either spraying or brushing.

Suggested dosage

It is suggested to use between 6%~10%.

Widely applicable

It is applicable for all types of solvent based and water based binders.

Using method

Mix with binder, accessories, additive, solvent, and be dispersed while using.

Environment friendly

Inoxious and environment friendly. SGS report to prove the metal content issue.

Anticorrosion Pigments,

Inkjet Receptive Coating,

Matting Agent

Product Categories : Anti Corrosive Pigment

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.