Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

The Matting Agent in coating is a kind of additive that can change the optical properties of the paint film surface, can form a fine rough surface of the paint film, and the light project on the paint film can produce diffuse reflection, so as to achieve matte effect. To form a fine rough surface, the coating needs to meet two conditions:(1) there are a large number of matting agent with suitable particles size; (2) produce suitable volume shrinkage during the drying process of the paint film. At the same time, matting agent in coatings needs to meet the requirements as the follows:(1) the refractive index is as close as possible to the refractive index of the film forming resin 1.4~1.6; (2) good wear resistant and scratch resistant; (3) good dispersion and redispersion performance in coatings.

Commonly used matting agents are divided into two categaries:organic and inorganic matting agents. Organic matting agents are always thermosetting polymersm; the inorganic matting agents are mostly silica matting agents. Besides that, there are also wax matting agents, wax modified silica agents and so on. The refractive index of amorphous silica is 1.46, which is closer to the refractive index of most resins commonly used in industrial coating filed. And it has good optical properties in the coating film, so it has become the preferred material used in high-grade coating matting agents.

Do you know the common ways to synthesize silica? There are three methods:

· the fume method,

· the precipitated method

· the gel method.

It will be introduced in the following to help you know about the difference between them.

1. Fume Silica

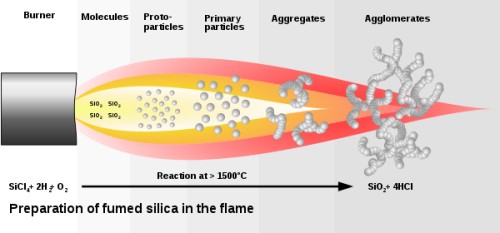

Fume silica is a ultrafine powder with hydroxyl and absorbed water on the surface formed by the high temperature hydrolysis of silicon halide in the hydrogen and oxygen flame and combustion process, and the silica primary particles collide with each other to form secondary particles and form a chain, which has the characteristics of lager specific surface area, high chemical purity and good dispersion. The process of fume silica is show in figure:

2. Precipitation Silica

Precipitation silica is form by the reaction of sodium silicate and acid, and precipitated hydrate after the reaction is washed, filtered, dried and other process to form a product. The precipitation silica has the advantages of simple process condition and low cost, but it have problems such as small specific surface area, small pore volume and wide pore size distribution.The reaction principle is like an equation.

3. Gel Silica

The preparation principle of silica gel is similar to that precipitation silica, and its preparation process usually includes two processes of sol-gel and drying. In the sol-gel process precursor is hydrolyzed and polycondensed to generate a gel with fine porous and network structure, and then through a suitable drying process can be maintain under the premise of maintaining the original structure of the gel to remove a large amount of liquid inside, so as to prepare silica gel. The products have the advantages of lager specific surface area, lager pore volume and narrow particles size distribution, but its oil absorbed is low, the preparation process is relatively complicated, and the preparation cost is high.

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.